Robert Zubrin's Nuclear Salt Water Rocket (NSWR) design is a rocket that uses known physics and engineering . There are versions that could reach 7-8% of light speed. The use of low grade uranium enrichment for a more near term version is the one that is often described. However, if weapons grade uranium (90% enrichment) is used then he exhaust would be at 1.575% of the speed of light. A 30,000 ton ice asteroid and 7500 tons of uranium could propel a 300 ton payload including a crew to 7.62% of light speed.

This is a design which could enable interstellar travel with human crews and even colonization. The amount of uranium needed is within the range of what is currently mined. I estimate the costs and timeline to develop the first interplanetary version at $10-30 billion and 10-30 years.

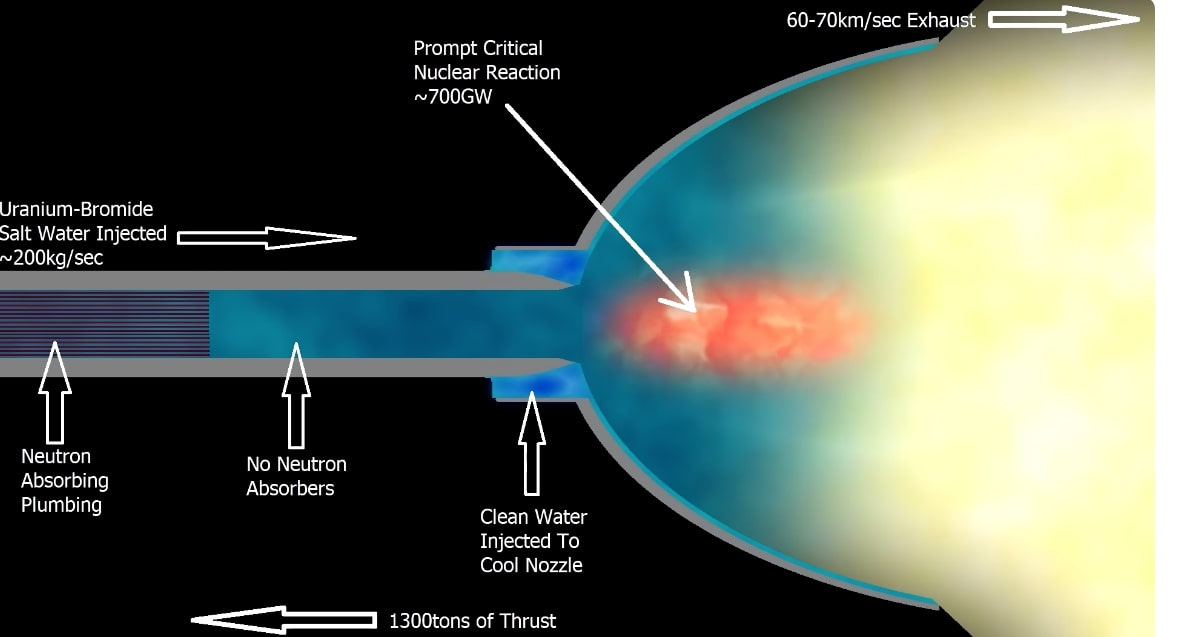

One of key parts of the engineering is to use water to protect the nozzle from the intense heat of the system. A combination of the coatings and space between the pipes would prevent the solution from reaching critical mass until it was pumped into a reaction chamber. It would reach critical mass and it being expelled through a nozzle to generate thrust. The nozzle would be protected by running water.

Scott Manley calls it a constant Chernobyl rocket. It is a nuclear reactor constantly at meltdown temperatures. The rocket was designed so that the liquid flow rate or velocity was what mattered most in the process, not what it was made out of. Robert Zubrin argued that if the proper velocity was chosen for the liquid traveling through the reaction chamber, the site of maximum fission release could then be located at the end of the chamber, thus allowing the system to remain intact and safe to operate.

The NSWR is a vehicle with ISP at the best ion drive levels or beyond and operating with hundreds of gigawatts of power.

The weaker NSWR engine analysis assumed a very low yield of 0.1% and a modest enrichment of 20%. The potential ultimate performance of a NSWR if more optimistic values are assumed.

An NSWR utilizing a 2% uranium bromide solution with 90% enriched U233, and obtaining a 90% fission yield. Assuming a nozzle efficiency of 0.9, the exhaust velocity of this system will be 4725 km/s, or about 1.575% of the speed of light (a specific impulse of 482,140 seconds). If the 300 tonne Titan mission spacecraft is endowed with 2700 tonnes of propellant (for a mass ratio of 10) a maximum velocity of 3.63% of speed of light could be obtained, allowing the ship to reach Alpha Centauri in about 120 years.

Deceleration could be accomplished without the use of substantial amounts of rocket propellant by using a magnetic sail (or "magsail") to create drag against the interstellar medium.

If a small 30,000 tons ice asteroid was used, then the final velocity could be 7.62% of the speed of light one could envisage a group of interstellar emigrants selecting a small ice asteroid with a mass of 30,000 tonnes and using it as propellant (together with 7,500 tonnes of uranium obtained elsewhere) for a 300 tonne spacecraft. In this case the ship could obtain a final velocity of about 7.62% light speed, and reach Alpha Centauri in about 60 years.

A group of astronauts who initiated the trip in their twenties would be alive a the end of the journey. The first generation children would still be in their prime.

I first wrote about it almost 10 years ago in 2016. Zubrin published the design in 1991.

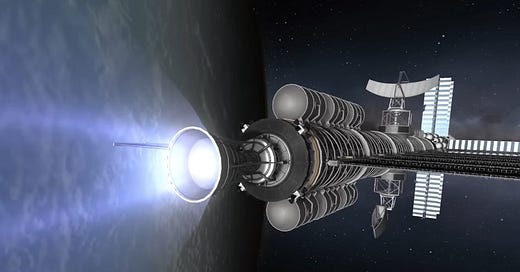

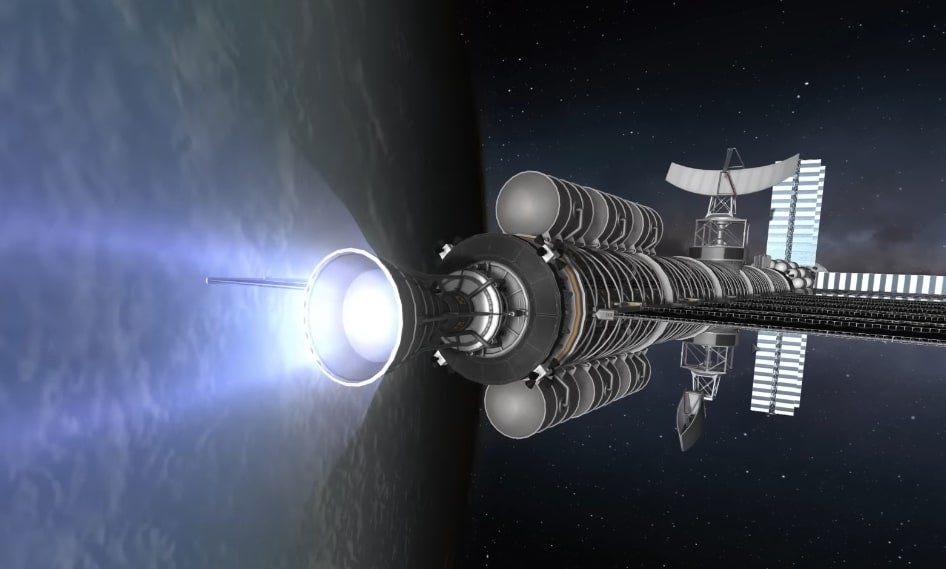

It is a rocket that would be deployed in orbit or somewhere else off planet. NSWR is constructed of a bundle of boron-carbide coated pipes, each containing an aqueous solution of uranium or plutonium salt These pipes empty into a single long cylindrical plenum pipe of larger diameter, which terminates in a rocket nozzle. When the rocket is to be fired, the aqueous solution held in the pipe bundles is emptied into the plenum. When the plenum has filled to a certain point, the fluid assembly within it exceeds critical mass and goes prompt supercritical, with the neutron flux concentrated on the downstream end due to neutron convection. Enormous amounts of energy are generated within this region, flashing the solution to steam which then streams down the plenum pipe towards the nozzle, convecting the exponentially growing fission chain reaction with it. As the solution continues to pour into the plenum from the borated storage pipes, a steady-state condition of a moving detonating fluid can be set up within the plenum.

Assuming a solution of 2 atoms of 20% enriched uranium per 100 molecules of water and a fission yield of 0.1% is obtained, the specific impulse produced will be about 7,000 seconds. This is comparable to that available from electric propulsion (EP). However, unlike an EP system, a NSWR is not power limited (since waste heat is eliminated with the propellant) and systems with jet power ratings of thousands of megawatts are obtainable. The NSWR can thus deliver its very high specific impulse at thrust levels of the same magnitude as chemical engines, or about 4 orders of magnitude greater than that of a multimegawatt EP system. The NSWR system is simple and lightweight. Shielding considerations are minimized by the fact that almost no radioactive inventory travels with the vehicle. On the other hand, the exhaust stream from the NSWR is extremely

radioactive, which limits the use of the device to orbit transfer propulsion, despite its high thrust to weight.

Could the Reactions Be Improved?

The NSWR projects achieving a 90% fission yield. 90% of the uranium fissions in the chamber, an ambitious figure given the rapid expulsion of material.

Possible improvements include:

Increasing Fission Yield:

Higher Concentration: The 2% uranium bromide solution could be increased, raising energy density and potentially exhaust velocity. However, this risks criticality in storage or injection, necessitating neutron absorbers or precise geometry control.

Neutron Reflectors: Surrounding the reaction chamber with materials like beryllium or graphite could reflect neutrons back, boosting the fission rate. This could push the yield closer to 100%, though 90% is already near the practical limit given the continuous-flow design.

Longer Residence Time: Retaining the solution in the chamber longer might increase fission, but this could reduce thrust or complicate the design.

Exhaust Velocity Boost

Exhaust velocity depends on temperature and molecular mass.

The fission energy (~200 MeV per event) already drives the water to plasma temperatures (millions of Kelvin), dissociating it into H and O ions. Lighter propellants (e.g., hydrogen) could raise velocity, but uranium salts don’t dissolve in hydrogen, and water’s abundance (e.g., from ice asteroids) is a key advantage.

Enhancing plasma conditions or using magnetic fields to accelerate ions might increase velocity but this requires advanced technology.

The 90% fission yield and 4,725 km/s exhaust velocity are already highly optimized. Marginal gains might be possible with reflectors or concentration tweaks.

The main challenge for NSWR is the engineering to build and safely operate it.

Project Roadmap for NSWR Development (about 15-24 Years)

Phase 1: Bench-Scale Experiments (Non-Nuclear)

Objective: Validate the basic engineering principles of the NSWR using safe, non-nuclear materials.

Key Activities:

Storage and Injection Testing: Build small-scale models of the storage tanks and injection systems using surrogate solutions (e.g., non-radioactive heavy metal salts) that mimic the chemical properties of uranium salts. Test the ability to store and move these solutions without issues.

Criticality Control: Use neutron-absorbing materials (e.g., boron or cadmium surrogates) and specific tank designs to prevent simulated "criticality." Compare results to computer models to ensure accuracy.

Nozzle Cooling: Test a small water-cooling system for the rocket nozzle using high-temperature heat sources (like plasmas) to mimic the heat of a nuclear reaction. Check if it can handle the heat without breaking.

Duration: 1-2 years

Outcome: Proof that the storage, injection, and cooling systems work as expected in a safe, non-nuclear setup.

Phase 2: Subcritical Nuclear Tests

Objective: Test the system with real nuclear materials, but in a way that avoids a full nuclear reaction (subcritical state).

Key Activities:

Subcritical Testing: Use low-concentration uranium salt solutions (e.g., natural uranium) in designs that can’t go critical. Measure how neutrons behave to confirm our models are correct.

Safety Checks: Test safety features like neutron absorbers and emergency stop systems to ensure no accidental reactions happen.

Injection Precision: Fine-tune the injection system to control the flow of nuclear solution accurately with real materials.

Duration: 2-3 years

Outcome: Confidence that the system behaves predictably with nuclear materials and stays safe under subcritical conditions.

Phase 3: Criticality Tests in a Controlled Environment

Objective: Achieve a controlled nuclear reaction (criticality) with a tiny amount of material in a secure setting.

Key Activities:

Small Reaction Chamber: Build a miniature reaction chamber using a small amount of highly enriched uranium (e.g., a few grams). Test it in a remote facility with strong safety measures.

Controlled Reaction: Slowly adjust the solution or design to start a fission reaction, then stop it safely. Monitor the energy and stability closely.

Data Refinement: Use the results to improve our models of how the reaction works.

Duration: 2-3 years

Outcome: Proof that we can start and stop a nuclear reaction safely on a small scale.

Phase 4: Integrated System Tests

Objective: Combine the reaction chamber, nozzle, and cooling into a working ground-based prototype.

Key Activities:

Prototype Build: Connect the reaction chamber to a nozzle and cooling system, adding controls for injection and safety.

Low-Power Tests: Run the system at low power (e.g., lower uranium concentration) to check thrust and cooling. Measure how much push it generates and if it stays intact.

Power Increase: Gradually ramp up the power by tweaking the solution or flow, watching for any problems with heat or structure.

Duration: 3-4 years

Outcome: A fully working ground prototype that produces thrust and handles heat as expected.

Phase 5: Prototype Flight Tests

Objective: Fly a small NSWR prototype in space to test it in real conditions.

Key Activities:

Flight Design: Build a lightweight version of the NSWR that fits on a small spacecraft with basic systems (e.g., power and communication).

Short Flights: Launch it on suborbital or short orbital missions. Test short bursts of the engine in space, focusing on starting and stopping it safely.

Performance Check: Measure thrust, efficiency (specific impulse), and how it works in a vacuum and microgravity.

Duration: 3-5 years

Outcome: Proof that the NSWR works in space, with data to guide improvements.

Keep reading with a 7-day free trial

Subscribe to next BIG future to keep reading this post and get 7 days of free access to the full post archives.